Wrote a research paper as well, but I can't share it until my mentor publishes the work. Coming soon!

1 hollow & 1 infilled sample

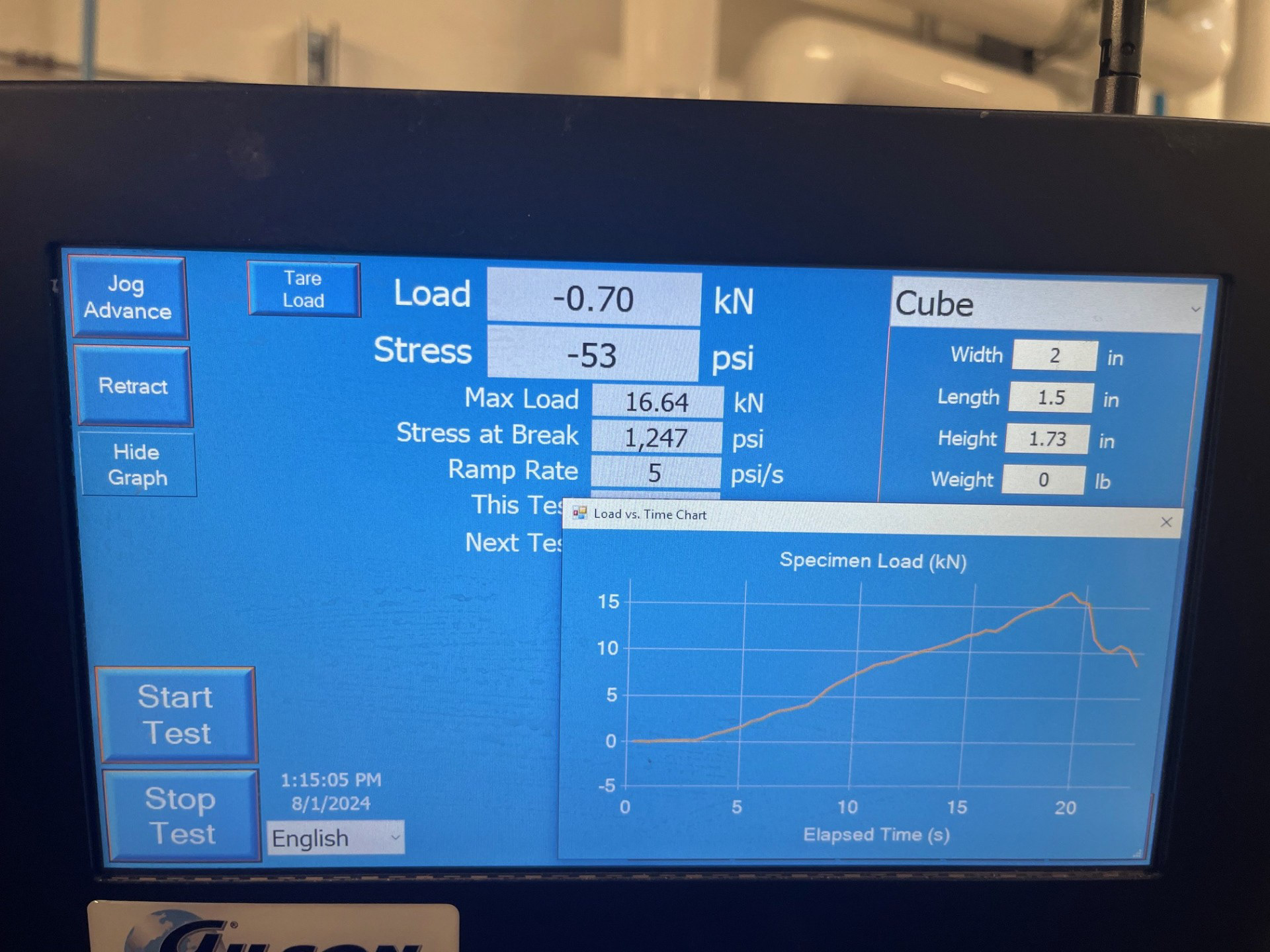

Compressive Strength Testing

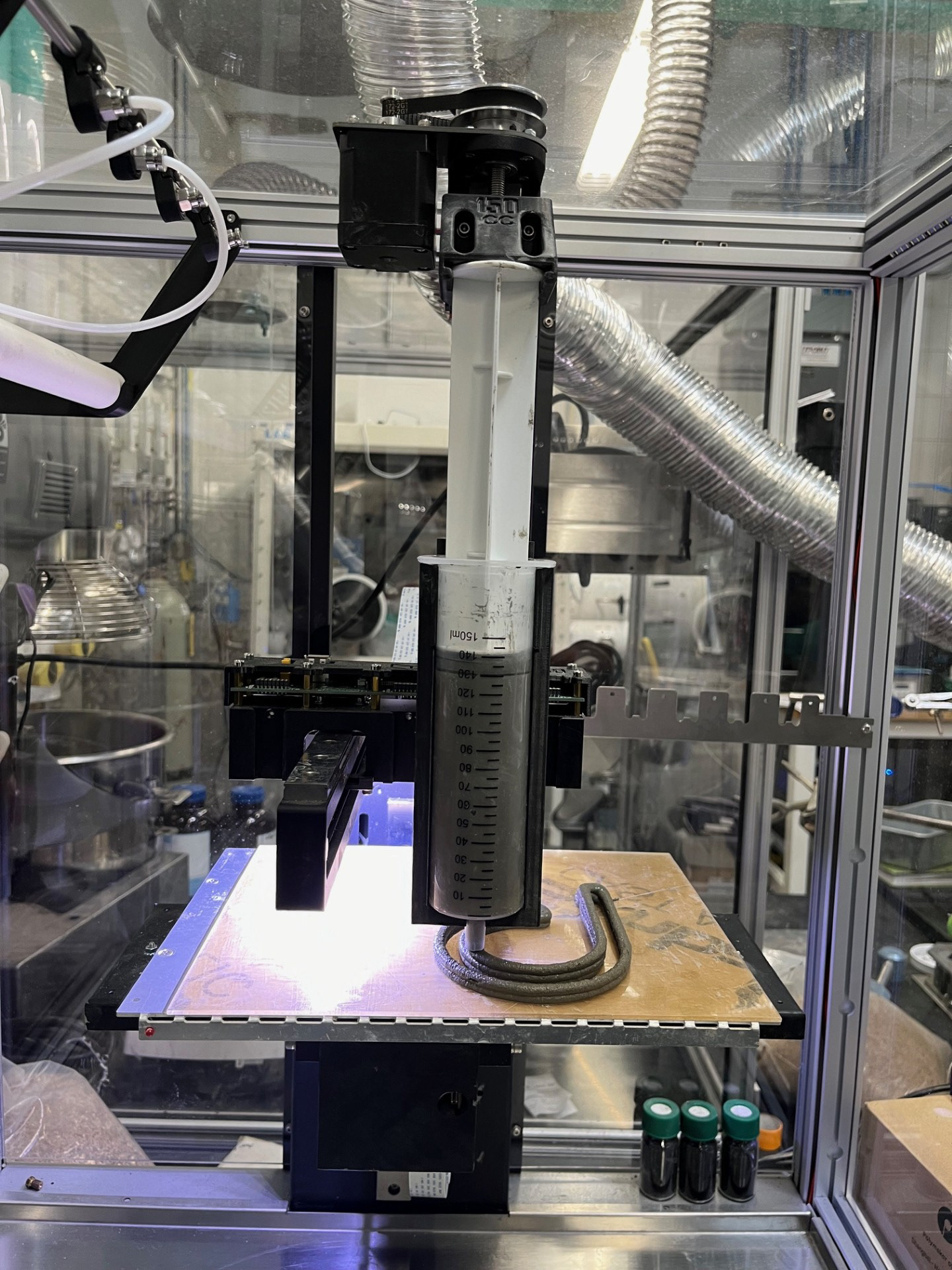

Printing Setup

Samples for testing

Thermal Conductivity Test

Fairly good wall sample

Iterations while achieving printability.

What I did:

For my summer project, I first optimized the parameters used for 3D-printing mortar mixtures at a small scale; this then allowed me to produce and characterize the performance of 3D-printed specimens in thermal conductivity and compressive strength. After an iterative process, I found a mixture with the required consistency and hardening characteristics that performed well when paired with the appropriate printer parameters. Using my results, I printed many samples and found that specimen printed with LignoCrete (a carbon-negative cement developed at NREL) achieved 51% the thermal conductivity but less than 40% the compressive strength of 3D-printed Portland Cement based mortars.

Learnings & Outcomes:

During my internship, I gained experience designing my own experiments, analyzing results, and validating data. In addition to the technical skills gained, I learned how to communicate my ideas clearly, maintain a mutually beneficial relationship with mentors, write a research paper/ create a poster, and many more workplace skills necessary to succeed in any future occupation. On a technical note, I learned about structural analysis, cement chemistry, additive manufacturing, experiment design, thermodynamics, and more.